Minimizing sound and vibration in water-source heat pumps

May 14, 2018 | By Karl Washburn

Dynamic power is used to move air and refrigerant in HVAC/R equipment. One unavoidable result of this dynamic application of power is sound and vibration. In a water-source heat pump (WSHP), both the compressor and supply fan generate sound and vibration, challenging the manufacturer, contractor/installer and builder/architect to provide an environment substantially free of intrusive sound and vibration.

SOUND AND VIBRATION: THE BASICS

Vibration is the repeated squeezing and stretching of material. If the material is a fluid, the vibration becomes sound. Vibration and sound transport energy through materials from one place to another. But they do not transport material, and the energy moves in waves. Like other types of energy transport, sound and vibration continue until they are blocked or dissipated. Because it travels in waves, sound can turn corners and squeeze through gaps–important attributes in controlling equipment sound and vibration.

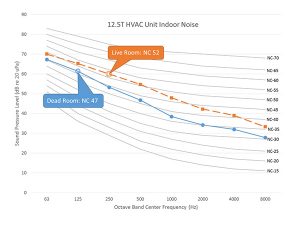

A 12.5-ton unit with a total sound power level of 86 dB (re 1 pW) has a Noise Criteria rating of NC52 in a live room (such as a grocery store) and an NC47 rating in a dead room (such as a medical waiting room).

Human hearing strongly influences ways we quantify sound. We can sense sound across an astounding range of amplitudes. The quietest sound most humans can hear is about 20 micropascals, while the threshold of hearing pain is about 20 pascals, a scale of one million. Rather than carry around lots of zeros, scientists express sound in decibels (dB). Named after Alexander Graham Bell, dBs convert powers of 10 into sums of 10, similar to the Richter scale for earthquakes. By convention, the threshold of human hearing is set to 0 dB, and pain occurs around 120 dB.

Because the dB can be used for almost anything (pressure, power and even voltage), it is a source of tremendous confusion, which affects the HVAC/R industry. The important thing to remember is a dB is always a relative measure. To know which type of dB is referenced, you must know what it is relative to, for example, pascals for sound pressure or watts for sound power.

Another aspect of human hearing lies in our changing sensitivity across frequencies (pitches). Our ears are insensitive to sound at low frequencies, sensitive in mid-frequencies and taper off at very high frequencies. Since microphones and sound meters do not discriminate with frequency, the A-weighting scale is often applied to sound measurements.

A-weighting is a frequency filter that emulates human ears. A-weighting can result in different dB levels compared to unweighted levels. When A-weighting is applied, it should be marked dBA or dB(A). Without this marking, confusion can result.

SOUND AND VIBRATION: WATER-SOURCE HEAT PUMPS

The compressor and supply fan are the two primary sources of sound and vibration in WHSPs. As compressors turn, any residual imbalance results in vibration. All compressors release high-pressure pulses of refrigerant, another source of sound and vibration. Most of the sound emanates from the canister housing the compressor, while vibration comes through the feet of the compressor and the tubing carrying refrigerant.

Supply fan blades individually push small slugs of air to raise air pressure in a plenum. This repeated pushing, along with turbulence that forms in and around the fan, generates sound.

In most configurations, a WSHP air inlet faces into the occupied space and conditioned air is released through one or more grilles. Usually the inlet is where compressor sound escapes, and the outlet is where fan sound escapes. There are many configurations, so this may not be true for all of them.

To reduce equipment sound, it must be blocked, absorbed or both. In a WSHP, the compressor casing is designed to contain (block) sound. Additionally, some inlet door designs include a layer of sound-absorbing material that helps reduce the remaining sound that escapes the housing. Likewise, the pressure plenum is designed to block line-of-sight between the fan and discharge grille, and sound-absorbing material lines the plenum to further reduce sound. Even with these features, the unit radiates sound. The installation must completely seal around the unit; even a small gap will defeat a wall’s sound-blocking capacity.

Mounting the compressor on soft isolators greatly reduces compressor vibration. Even so, vibration gets into the unit’s housing. It is critical that no part of the housing be allowed to touch the walls. Flexible duct collars are needed to separate the inlet and discharge grilles from the unit. In more sensitive applications, the housing should ride on additional isolators to reduce vibration at the floor.

RATING WSHP SOUND

North American manufacturers rate WSHP sound using the American Heating and Refrigeration Institute (AHRI) Standard 260. This standard specifies how to measure sound power levels, denoted LW, emanating from the air inlet, air outlet and housing. Sound power levels measured in compliance with AHRI 260 are listed in 8 octave bands, from 63 Hz (very low frequency) to 8,000 Hz (very high frequency). The dB levels in the unit’s technical specification are not the dBs we are accustomed to. These are dBs relative to 1 picowatt of power, not pressure. Furthermore, the levels are not A-weighted. They might seem very high at low frequencies (63 Hz and 125 Hz).

If the technical guide does not express sound power levels in compliance to AHRI 260, then you cannot be certain how sound levels were measured. Always insist on receiving this information as part of a submittal.

SOUND POWER, SOUND PRESSURE AND NOISE CRITERIA

Sound power is not what human ears hear; it is what equipment generates. That power is converted to sound pressure as it propagates out to the room. What is important to people, is what they hear. Not only do our ears colour sound, the acoustical environment greatly influences the amplitudes and frequencies we hear. One common way of expressing this complexity within the built environment is the Noise Criteria, or NC rating. This one-number metric roughly determines whether a given sound environment will be intrusive to normal listeners.

NC ratings are driven by the equipment’s sound power level, but they result from the effect of the room in which the sound is contained and the non-uniform way humans hear. Because NC ratings relate to how people feel about sound, they are sometimes used as de facto HVAC/R equipment requirements. For example, the city of Toronto, ON, sets limits on NC ratings for new multi-resident construction (Tarion Builder’s Bulletin No. 19).

More importantly, although there is an accepted way of calculating NC rating, there is no standard method for measuring it in the built environment. This leaves the equipment manufacturer, who has no direct control over NC rating, in a bind.

If you see an NC rating in the technical specification, there is no way of knowing how it was measured or whether it is reliable. If your project depends on an NC rating, then you must use AHRI 260-compliant sound levels, along with an acoustical model of the room and any ductwork, to estimate it. An acoustical consultant can be invaluable in such a situation.

CALL IN THE EXPERTS

All HVAC/R equipment generates sound and vibration, which manufacturers work to minimize. Because WSHPs share the same space with occupants, their internal design and proper installation are key to avoiding intrusive sound and vibration.

Although we interact directly with sound and vibration, they may seem mysterious and hard to describe. There are specific ways to express the amount and type of sound emanating from HVAC/R equipment. When you specify equipment, insist on receiving sound power levels properly certified to AHRI 260. When faced with an NC rating requirement, remember it must be calculated from the unit’s sound power levels and acoustical attributes of the room. No manufacturer can guarantee an NC rating, making the assistance of an acoustical consultant during design invaluable. <>

Karl Washburn, INCE Bd. Cert., is principal engineer with Johnson Controls, Inc. Washburn presented a session on sound and vibration at the launch of Johnson Controls’ vertical stacked water-source heat pump sound room in Ajax, ON. The condo-style room containing two working demos, allows customers to experience sound performance.

Sound vocabulary:

Sound – is a compressional vibration that propagates in an elastic medium.

Sound pressure – relates to the sound a human will experience. Sound pressure level depends on both the source and the environment, making it situation dependent.

Pascal – The International System of Units (SI) derived unit for pressure is the pascal. It is equivalent to one newton per square meter.

Micropascal – 1 pascal is equal to 1,000,000 micropascals.

Sound power – relates and depends only on the source of sound. In the case of equipment, sound power is the sound equipment generates. Unlike sound pressure, it is not situation dependent.

Watt – a measure of electrical power. As an amplifier processes sound, the output is measured in watts.

Picowatt – equal to one trillionth of a watt.

Vibration – the repeated squeezing and stretching of material.

Vibration isolation – the process of isolating an object, such as a piece of equipment, from the source of vibrations.

Decibels (dB) – Named after Alexander Graham Bell, a decibel is the unit scientists use to measure sound amplitude.

A-weighting scale – A-weighting is a frequency filter that emulates human ears.

dBA or dB(A) – dBA or dB(A) is a single number rating typically used to quantify sound as it is perceived by humans. When A-weighting is applied, it should be marked dBA or dB(A).

Frequency – the number of waves that pass a fixed place in a given amount of time. The frequency of sound is its pitch.

Hertz – Hertz (Hz) is the SI derived unit of frequency and is defined as one cycle per second.

Octave band – a frequency band where the highest frequency is twice the lowest frequency.Noise Criteria – rating is a one-number metric that roughly determines whether a given sound environment will be intrusive to normal listeners.

Air-conditioning Heating and Refrigeration Institute (AHRI) – The AHRI Technical Committee on Sound (TCoS) has responsibility for standards related to sound.